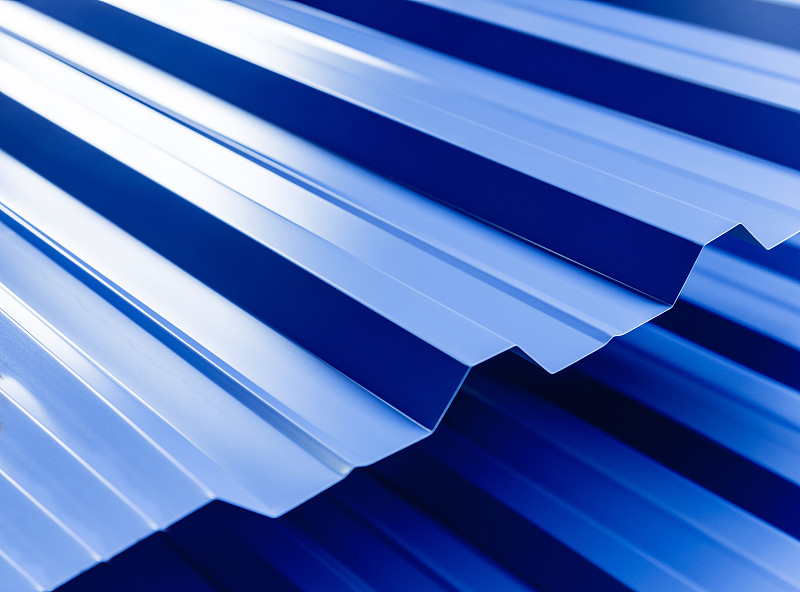

Recently, a new steel plate coating production line of a color coated sheet enterprise in Shandong was put into operation. Its organic waste gas has achieved clean emission through an efficient treatment system, marking the successful completion of the second VOCs treatment cooperation between CADAIR and the enterprise.

The waste gas treatment solution previously provided by CADAIR for the enterprise’s first coating line has been highly recognized for its stable operation and excellent effect. With the enterprise’s capacity expansion and the addition of a new coating line, CADAIR has once again become the preferred partner by virtue of its technological and cooperative advantages.

Project Background: Facing the Challenges of VOCs Treatment in Color Steel Spraying and Laying a Solid Foundation for Green Development

In the production of color coated sheets, the coating process will generate VOCs containing No. 100 solvent oil, n-butanol and other components. Direct emission without treatment not only pollutes the environment, but also affects the compliant development of the enterprise.

The waste gas treatment of the new production line is particularly challenging: the air volume is 40,000 m³/h and the concentration is 3,500 mg/m³, posing higher requirements for the pertinence and stability of the technical scheme.

Technical Scheme: Precise Empowerment of Three-Bed RTO System to Solve the Pain Points of Waste Gas Treatment

Based on the experience of the first cooperation, CADAIR customized a three-bed RTO waste gas treatment scheme for the enterprise. This technology heats the waste gas to above 760℃ to oxidize and decompose VOCs into harmless substances; the three-bed design ensures continuous operation, while efficiently recovering waste heat to reduce energy consumption and balance economy.

Treatment Effect: Strictly Aligning with Local Standards to Achieve Environmental Compliance

After treatment, the concentration of non-methane total hydrocarbons (NMHC) in the emitted gas fully complies with Shandong Provincial Standard DB37/2801.5-2018, achieving compliant and clean emission. The project person in charge said that the second cooperation is based on trust, and CADAIR’s scheme not only solves environmental protection problems, but also takes into account operational economy.

Cooperation Value: From Supplier to Strategic Partner, Jointly Building an Industry Environmental Benchmark

CADAIR’s project director said that the re-cooperation is the owner’s recognition of its technology and services, and the customized scheme is its core advantage. This cooperation has consolidated the partnership between the two parties and provided a benchmark case for VOCs treatment in the color coated sheet industry.