In the design and manufacturing of waste gas treatment equipment, the choice of metal materials is critical for ensuring durability, corrosion resistance, and performance under different operating conditions. At CADAIR, we select stainless steel and carbon steel according to the specific demands of air pollution control equipment such as RTOs (Regenerative Thermal Oxidizers), catalytic oxidizers, and VOC treatment systems.

Stainless Steel in Waste Gas Treatment Equipment

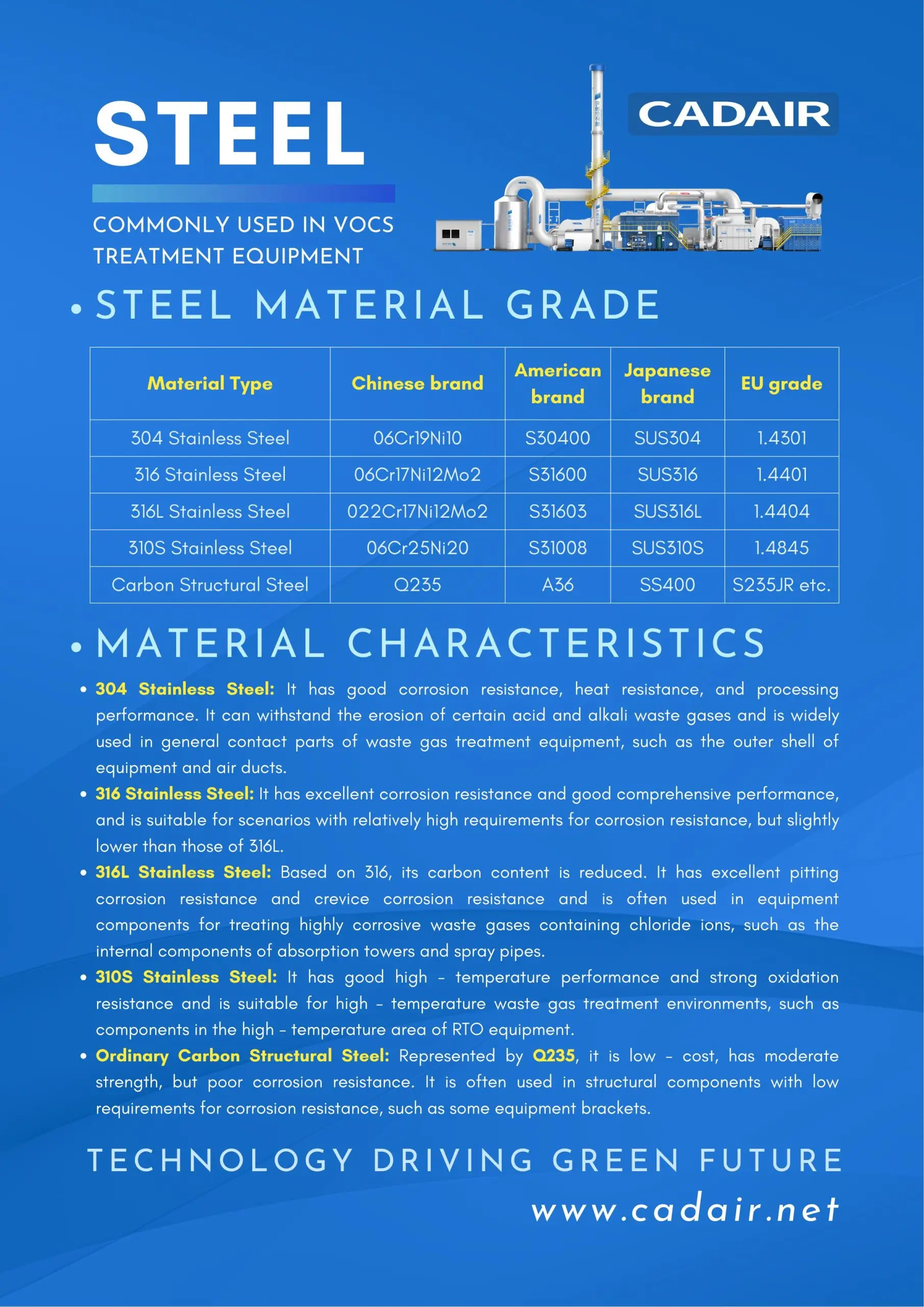

304 Stainless Steel

- Chinese grade: 06Cr19Ni10

- Composition: ~19% Cr, ~10% Ni

- Properties: Good corrosion resistance, heat resistance, and processing performance

- Applications: Widely used in outer shells, ducts, and general contact parts of air pollution control equipment where acid and alkali waste gases are present.

316 Stainless Steel

- Chinese grade: 06Cr17Ni12Mo2

- Composition: ~17% Cr, ~12% Ni, ~2% Mo

- Properties: Excellent corrosion resistance and mechanical strength

- Applications: Suitable for environments requiring higher corrosion resistance, used in VOC treatment units and spray components.

316L Stainless Steel

- Chinese grade: 022Cr17Ni12Mo2

- Improvement: Lower carbon content than 316, enhancing pitting and crevice corrosion resistance

- Applications: Ideal for handling highly corrosive waste gases containing chloride ions, such as internal components of absorption towers and spray pipes in waste gas treatment equipment.

310S Stainless Steel

- Chinese grade: 06Cr25Ni20

- Composition: ~25% Cr, ~20% Ni

- Properties: Excellent high-temperature strength and oxidation resistance

- Applications: Used in high-temperature zones of RTO equipment, such as combustion chambers and heat exchange parts.

Carbon Steel in Waste Gas Treatment Equipment

Ordinary Carbon Structural Steel (Q235)

- Properties: Low cost, moderate strength, poor corrosion resistance

- Applications: Used in structural components, such as equipment brackets, where corrosion resistance is not a major concern.

High-Quality Carbon Structural Steel (45 Steel)

- Properties: Higher strength and better machining performance than Q235

- Applications: Suitable for parts requiring mechanical strength, such as fan shafts and moving components in pollution control equipment.

Conclusion

The performance and lifespan of waste gas treatment equipment depend heavily on the proper selection of materials. Stainless steels (304, 316, 316L, 310S) provide excellent resistance against corrosion and high temperatures, making them essential for RTOs, catalytic oxidizers, and VOC treatment systems. Meanwhile, carbon steels (Q235, 45 steel) offer cost-effective solutions for structural and mechanical parts.

👉 Learn more about CADAIR’s Environmental Protection Equipment and how we combine material expertise with advanced technology to deliver durable and efficient waste gas treatment solutions.