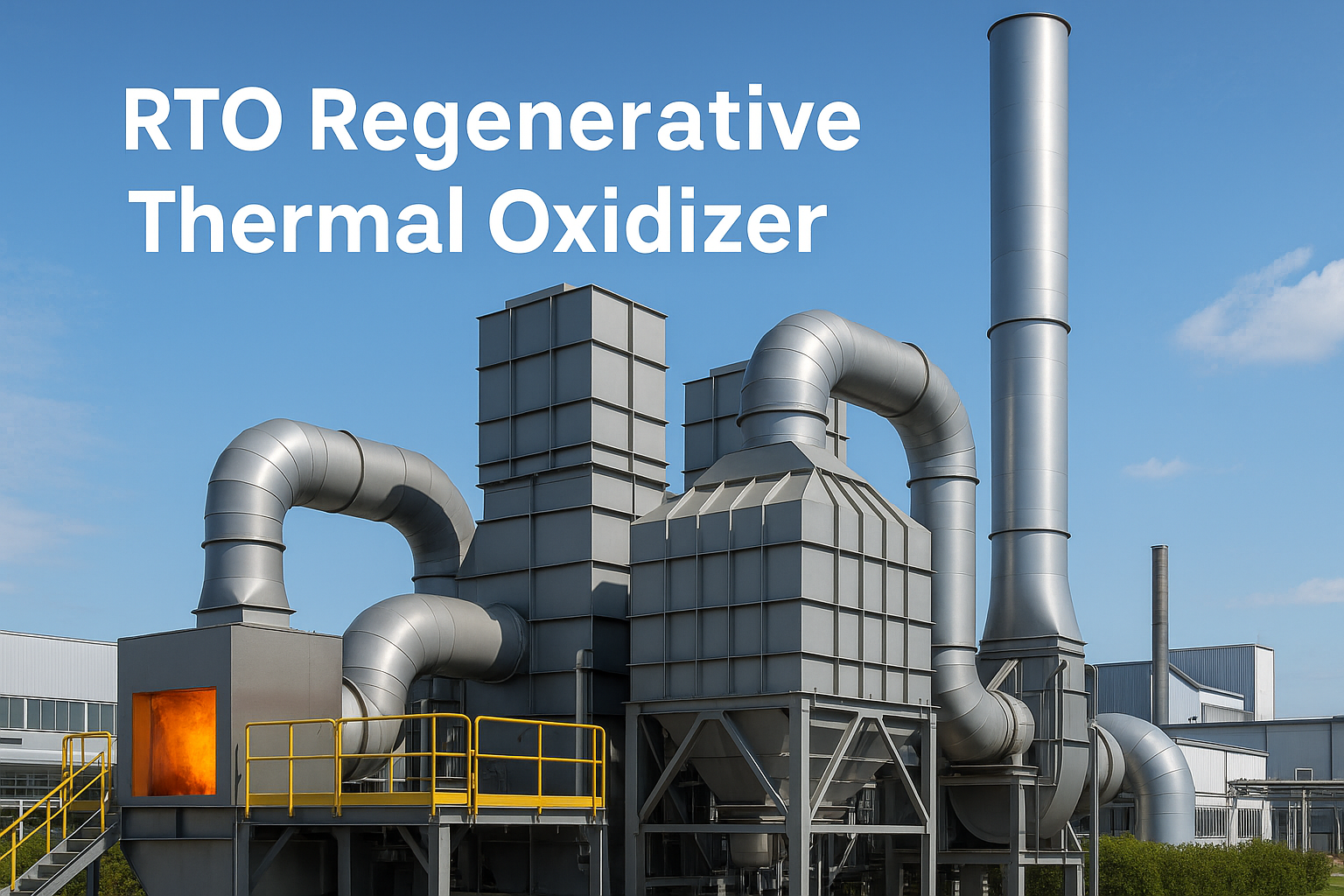

What is an RTO (Regenerative Thermal Oxidizer)?

A Regenerative Thermal Oxidizer (RTO) is an advanced air pollution control system designed to remove volatile organic compounds (VOCs) and hazardous air pollutants through high-temperature oxidation. It is widely used in industries with high VOC emissions due to its energy efficiency and reliability.

👉 Visit our Homepage for a full overview of CADAIR solutions.

How Does an RTO Work?

- Exhaust air passes through ceramic heat exchange beds, preheating before entering the combustion chamber.

- VOCs are oxidized at 800–1000°C into harmless CO₂ and H₂O.

- Heat is recovered and reused, resulting in thermal efficiency up to 95%.

👉 Explore our Products Page for details.

Advantages of RTO Systems

- VOC destruction efficiency ≥99%

- Low operating costs thanks to regenerative heat recovery

- Long service life with robust ceramic heat media

- Flexible for different industrial applications

👉 Read our Case Studies for real-world applications.

Industrial Applications of RTO

- Petrochemical industry – Treatment of hydrocarbons and process gases

- Printing & Coating – VOC abatement from solvent-based operations

- Electronics & Packaging – Emission control for precision industries

- Pharmaceuticals – Safe handling of toxic gases

👉 Learn more in our Solutions Page.

Why Choose CADAIR RTO?

CADAIR provides custom-engineered RTO systems with advanced heat recovery, ensuring maximum efficiency, regulatory compliance, and sustainable performance.

👉 Contact us through our Homepage to start your project.