Vulcanization, a core tire production process, was once an industry environmental pain point due to high-temperature flue gas with complex components. The waste gas treatment project for the vulcanization workshop of a benchmark green tire enterprise in Pingluo, Ningxia, has successfully solved this problem and passed acceptance!

Project Background: Green Enterprise’s Environmental Initiative

The enterprise has an annual output of 20.1 million high-performance radial tires, with 56 vulcanizing machines in the workshop. High-temperature flue gas containing dust, odor and VOCs is emitted during mold opening after vulcanization, with concentrated emissions that are hard to treat stably via traditional single processes. Amid stricter environmental requirements, solving vulcanization flue gas treatment has become key to its green and sustainable development.

Core Project Information

- Waste Gas Source: Hot flue gas during vulcanizing machine mold opening

- Treated Air Volume: 200,000m³/h

- Main Pollutants: Dust, VOCs

Customized Treatment Plan:Layer-by-layer filtering and step-by-step breaking through

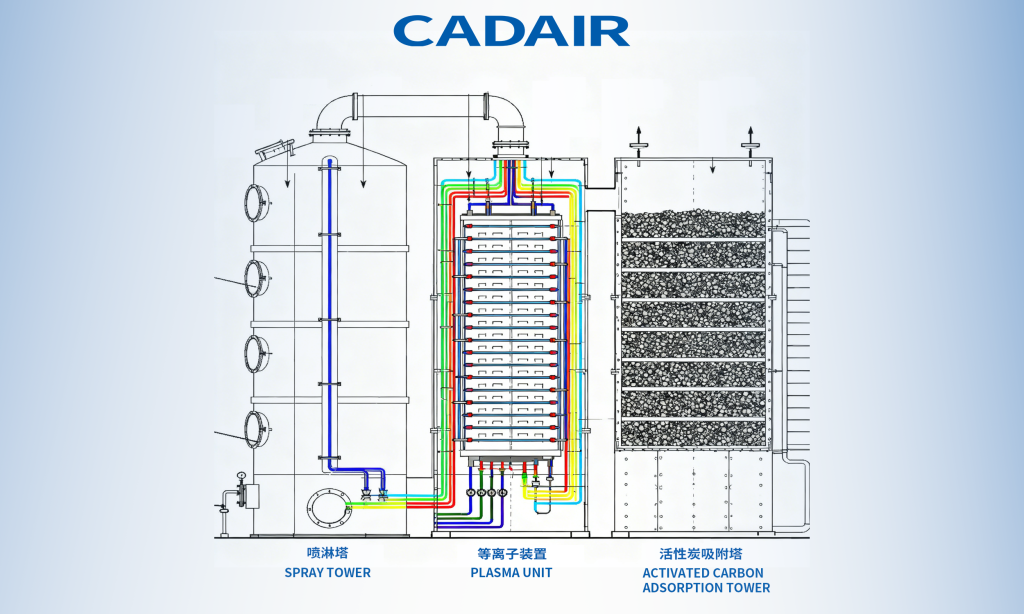

CADAIR designed a combined process of “Spray + Injection Plasma + Activated Carbon Adsorption” based on flue gas characteristics, achieving efficient purification through layer-by-layer filtration.

· Spray Pretreatment: Dust Removal

Flue gas first enters the spray system, where most dust particles are removed via efficient washing, reducing subsequent process loads and laying the foundation for deep purification.

· Plasma Deep Purification: Pollutant Decomposition

Initially purified flue gas enters the plasma unit, where active particles decompose odor molecules and VOCs into harmless substances like water and CO₂, realizing fundamental pollutant degradation.

· Activated Carbon Adsorption: Terminal Emission Guarantee

As the system’s “safety net”, activated carbon deeply adsorbs residual odor and organics, ensuring clean, odorless emissions and stable compliance.

This project not only solves the enterprise’s environmental issues but also sets an industry example, demonstrating a feasible path for traditional manufacturing’s green transformation. It proves that “environmental protection is not a burden but an opportunity for technological upgrading and sustainable development”.

Adhering to the concept of “Understanding Processes, Implementable Solutions”, CADAIR focuses on waste gas treatment R&D and implementation, providing customized full-process environmental solutions to help enterprises uphold environmental bottom lines and achieve high-quality development.