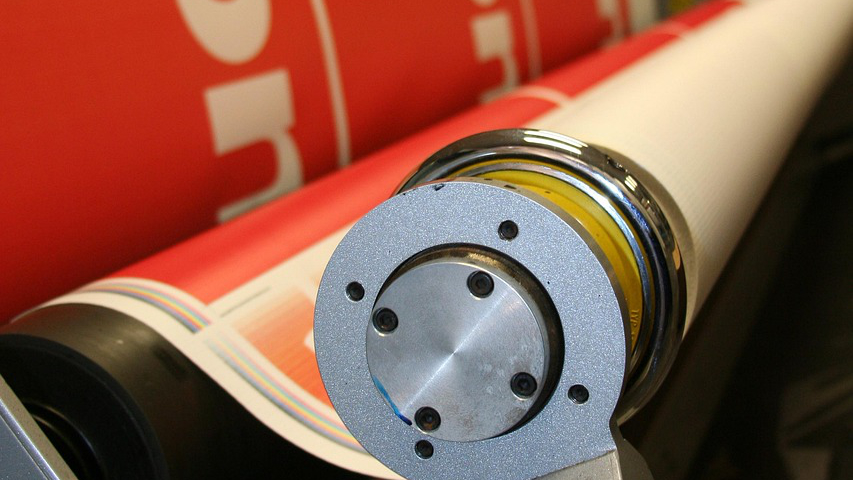

| • Printing process section | |

| Gravure printing | the peak concentration of ethyl acetate reaches 3,000–5,000 mg/m³ (60–80% of the total solvent), and the residual amount of toluene is 50–150 mg/m³ |

| Flexographic printing | ethanol/isopropyl alcohol mixed solvent (boiling point difference of 40 ℃), emission concentration fluctuation of 200–800 mg/m³ |

| UV curing | Active diluent (acrylates) residual 20–50 ppm with ozone by-products (concentration 5–10 mg/m³) |

| • Composite coating section | |

| Dry Composite | The instantaneous emission of ethyl acetate accounts for 90% of the total process, and the concentration gradient is 800–1,500 mg/m³ |

| Solvent-free composite | trace MDI monomer escape (concentration 0.5–2 ppm), accompanied by atomized particles of silicone oil (D50=1–3 μm) |

| Hot melt adhesive coating | paraffin hydrocarbon volatilization (C20–C30 accounted for 40–60%), exhaust gas temperature maintained 80–120 ℃ |

| • Post-processing section | |

| Cutting process | ink secondary volatilization (benzene series accounted for 25–35%), PM₂.₅ particulate flux 0.5–1.2 g/h |

| Bag heat sealing | PE/PP film thermal decomposition to produce low molecular aldehydes and ketones (formaldehyde concentration 10–30 mg/m³) |

ester/alcohol/benzene series form azeotrope (boiling point interval 60-140℃), traditional condensation efficiency attenuation 40-60%

When the gravure press changes the plate, the VOCs concentration jumps from 500mg/m³ to 4,500mg/m³ in 5 minutes

The lower explosive limit of ethyl acetate (2.0%VOL) overlaps critically with the working concentration (0.5-1.8%VOL)

large exhaust gas temperature gradient (40-130 ° C), conventional heat exchanger efficiency <50%